Metal cutting circular saw blades

Let’s dive into metal cutting circular saw blades and help you learn more about these essential tools. Picking the right blade for working with metal really matters, it’s the difference between getting clean, accurate cuts and staying safe while you work.

We’ll talk about the different tooth patterns you’ll see and why using the wrong blade can be risky.

By the end of this guide, you’ll know what to look for when choosing and using circular saw blades for metal.

Stay smart, stay safe, and get the best results from your tools.

Key Takeaways:

- Material: Choose the right circular saw blade material based on the material you need to cut. For example, carbide-tipped blades are best for cutting hard materials like metal while high-speed steel blades are suitable for cutting softer materials like wood.

- Number of Teeth: The number of teeth on a circular saw blade affects the smoothness of the cut. More teeth result in a finer cut, while fewer teeth are better for faster, rough cuts in thicker materials.

- Blade Size: Check the diameter and thickness of the circular saw blade to ensure it fits your saw and can handle the depth of cut you need. Using the correct size blade can improve cutting efficiency and minimize accidents.

Types of Metal Cutting Circular Saw Blades

The metal cutting circular saw blades come in various types, each specifically designed for different cutting applications. Understanding the differences between these blades can help you achieve optimal results in your metal cutting projects. Below is a breakdown of the common types of metal cutting circular saw blades:

| Blade Type | Description |

| High-Speed Steel (HSS) Blades | Assuming |

| Carbide-Tipped Blades | Even |

| Abrasive Blades | Blades |

| Diamond Blades | Assuming |

High-Speed Steel (HSS) Blades

Let’s say that you are looking for a versatile and cost-effective option, then High-Speed Steel (HSS) blades are a popular choice for cutting through mild steel, aluminum, and other soft metals.

These blades are known for their durability and ability to maintain their sharpness even at high temperatures, making them ideal for a variety of metal cutting applications.

Carbide-Tipped Blades

Even though Carbide-Tipped Blades are more expensive upfront, they offer superior cutting performance and longevity compared to other blade types. The carbide tips provide added strength and durability, allowing these blades to cut through hard metals such as stainless steel and cast iron with ease. Additionally, carbide-tipped blades require less maintenance and are less likely to overheat during prolonged use.

Abrasive Blades

Blades

Diamond Blades

Assuming

Factors to Consider When Choosing a Blade

Despite the wide range of options available, selecting the right metal cutting circular saw blades for your needs doesn’t have to be overwhelming.

By considering a few key factors, you can ensure that you are equipped with the best blade for the job. Recognizing these factors can help you make an informed decision.

Material to be Cut

You should first consider the material you will be cutting. Different blades are designed to handle specific materials, such as aluminum, steel, or stainless steel. Using the correct blade for the material will result in cleaner cuts and prolong the life of the blade.

Thickness of the Metal

Little attention is crucial to the thickness of the metal you will be cutting. Thicker metals require blades with fewer teeth to prevent overheating and ensure efficient cutting. Choosing the right blade thickness will improve the performance and longevity of the blade.

The type of metal being cut impacts the blade selection. Harder materials require diamonds or carbide blades, while softer materials can be cut with high-speed steel. Selecting the appropriate blade ensures a clean cut and prolongs the life of the blade.

Type of Cut Required

One imperative consideration is the type of cut you need to make. Whether you require straight cuts, plunge cuts, or crosscuts, there is a specific blade designed for each application. Choosing the right blade type will result in accurate and efficient cutting.

Saw Compatibility

Now, when selecting a blade, it is crucial to consider the compatibility with your circular saw. Not all blades fit all saws, so ensure that the blade you choose is compatible with your tool. Choosing a compatible blade will guarantee safety and optimal performance.

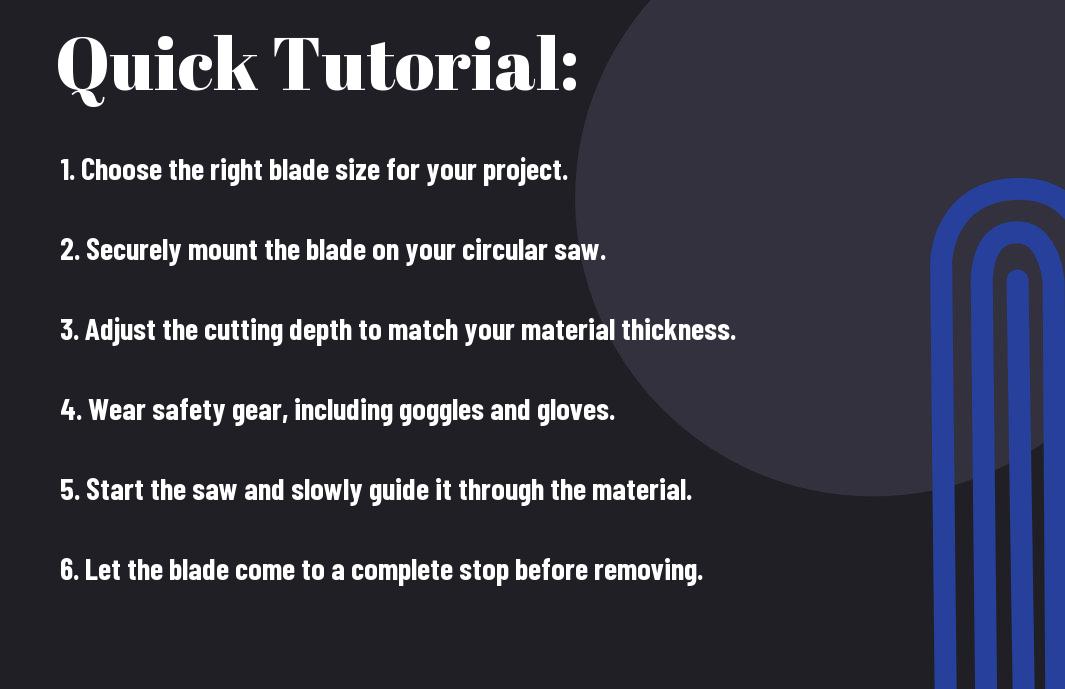

Using Metal Cutting Circular Saw Blades

Safety Precautions

Many accidents can be prevented by following proper safety precautions when using metal cutting circular saw blades.

If you are not familiar with the equipment or operating procedures, it is important to read the user manual thoroughly before starting any work. Always wear safety goggles and gloves to protect yourself from flying debris and sharp edges.

Blade Installation and Alignment

If you are unsure about blade installation and alignment, seek guidance from a professional or refer to the manufacturer’s instructions.

Ensure that the blade is securely fastened and aligned properly on the saw to prevent it from coming loose during operation.

Cutting Techniques and Tips

Using the right cutting techniques and tips can help you achieve clean and precise cuts with your metal cutting circular saw blade.

- Always set the correct blade speed and feed rate for the material you are cutting.

- Secure the workpiece firmly in place to prevent it from moving during cutting.

- Use a cutting lubricant to reduce friction and heat buildup.

After you have finished cutting, remember to turn off the saw and wait for the blade to come to a complete stop before removing the workpiece.

Maintenance and Care of Blades

Using metal cutting circular saw blades

requires you to properly maintain and care for them to ensure optimal performance and longevity.

You should regularly inspect the blades for any signs of wear or damage, such as dullness or missing teeth. Clean the blades after each use and store them in a dry place to prevent rusting. Sharpen the blades when necessary to maintain their cutting efficiency. Regular maintenance will not only prolong the life of the blades but also ensure safe and efficient cutting operations.

Troubleshooting Common Issues

Blade Wear and Tear

After prolonged use, metal cutting circular saw blades can experience wear and tear, leading to reduced cutting efficiency and quality. An inspection of the blade should be conducted regularly to check for signs of dullness, chipping, or warping that may affect performance.

Improper Cutting Speeds

Blade speed plays a crucial role in the cutting process. An incorrect cutting speed can result in a range of issues, including overheating, excessive wear, and poor cut quality. Blade manufacturers provide recommended speeds based on the material being cut, and it’s important to adhere to these guidelines for optimal performance.

Blade speed is calculated based on the material being cut and the blade’s diameter. For instance, cutting thick metal at too high a speed can cause the blade to heat up excessively, leading to premature dulling and potential damage to the workpiece.

Blade Vibration and Noise

Even with proper blade speed, vibration and noise during operation can indicate issues with the blade or the saw. Excessive vibration can lead to rough cuts, uneven edges, and potential safety hazards. It is imperative to address these issues promptly to maintain cutting precision.

To reduce vibration and noise, ensure that the blade is securely mounted and balanced correctly. A loose or imbalanced blade can cause unnecessary stress on the saw, leading to erratic cutting performance and possible damage.

Cut Quality Problems

Some common cut quality problems include jagged edges, burrs, and uneven cuts. Tear-out, in particular, can be a sign of blade dullness or improper feed rate. Ensuring the blade is sharp and that the workpiece is adequately supported can help produce clean, precise cuts.

Tear-out can compromise the integrity of the workpiece and may require additional finishing processes to correct. Regular maintenance and monitoring of cutting conditions can help prevent such issues and prolong blade life.

Summing up

Collecting the right information about metal cutting circular saw blades is crucial for choosing the correct tool for the job. Understanding the different types of blades available, their features, and applications significantly impact the efficiency and effectiveness of your cutting tasks.

To explore various options of metal cutting circular saw blades, visit Metal – Circular Saw Blades.

FAQ

Q: What are Metal cutting circular saw blades?

A: Metal cutting circular saw blades are specialized tools designed for cutting various types of metal, such as steel, aluminum, and other non-ferrous materials. These blades are constructed with high-speed steel or carbide tips to withstand the hardness of metal and provide fast, efficient cutting.

Q: How do I choose the right metal cutting circular saw blade?

A: When deciding on a metal cutting circular saw blade, consider the type of metal you will be cutting, the thickness of the material, and the saw’s RPM (revolutions per minute). Choose a blade with the appropriate tooth count and material for optimal performance and longevity.

Q: How do I maintain metal cutting circular saw blades?

A: To keep your metal cutting circular saw blades in top condition, it is necessary to regularly inspect them for any signs of damage or wear. Clean the blades after use to remove debris and prevent buildup. Additionally, sharpen or replace blades as needed to ensure clean and efficient cuts.