Are circular saw blades high carbon steel

Curious if your circular saw blades are made of high carbon steel? Understanding the material of your tools is crucial for their performance and longevity. Circular saw blades are typically constructed from high carbon steel due to its durability and ability to maintain a sharp cutting edge. This type of steel offers exceptional strength and hardness, allowing the blades to withstand the intense friction and heat generated during cutting. High carbon steel also ensures precise and clean cuts while reducing the chances of blade dullness and deformation. Knowing the composition of your circular saw blades can help you choose the right blade for your specific cutting needs and ensure efficient and safe operation. Let’s investigate into the characteristics of high carbon steel circular saw blades to understand why they are a popular choice among professionals and enthusiasts alike.

Key Takeaways:

- Circular saw blades are typically made of high carbon steel: Most circular saw blades are made from high carbon steel due to its durability and ability to retain sharpness.

- High carbon steel provides strength and toughness: The high carbon content in the blades makes them strong and tough, allowing them to withstand the high speeds and cutting forces of the saw.

- Regular maintenance is important: To ensure optimal performance and longevity of circular saw blades, it is vital to perform regular maintenance, such as cleaning and sharpening.

Composition of Circular Saw Blades

Materials Used in Blade Manufacturing

One common material used in circular saw blades is high carbon steel. This type of steel is known for its durability and ability to hold a sharp edge, making it a popular choice for cutting through various materials with precision.

Advantages of High Carbon Steel in Blades

Assuming circular saw blades are made of high carbon steel, one of the key advantages is their strength and hardness. This makes them ideal for cutting through tough materials like hardwood and metal, providing clean and efficient cuts. Additionally, high carbon steel blades are known for their long-lasting sharpness, reducing the frequency of blade replacements.

Advantages: Circular saw blades made of high carbon steel are not only durable and strong but also offer exceptional sharpness retention, ultimately leading to cost savings and consistent cutting performance.

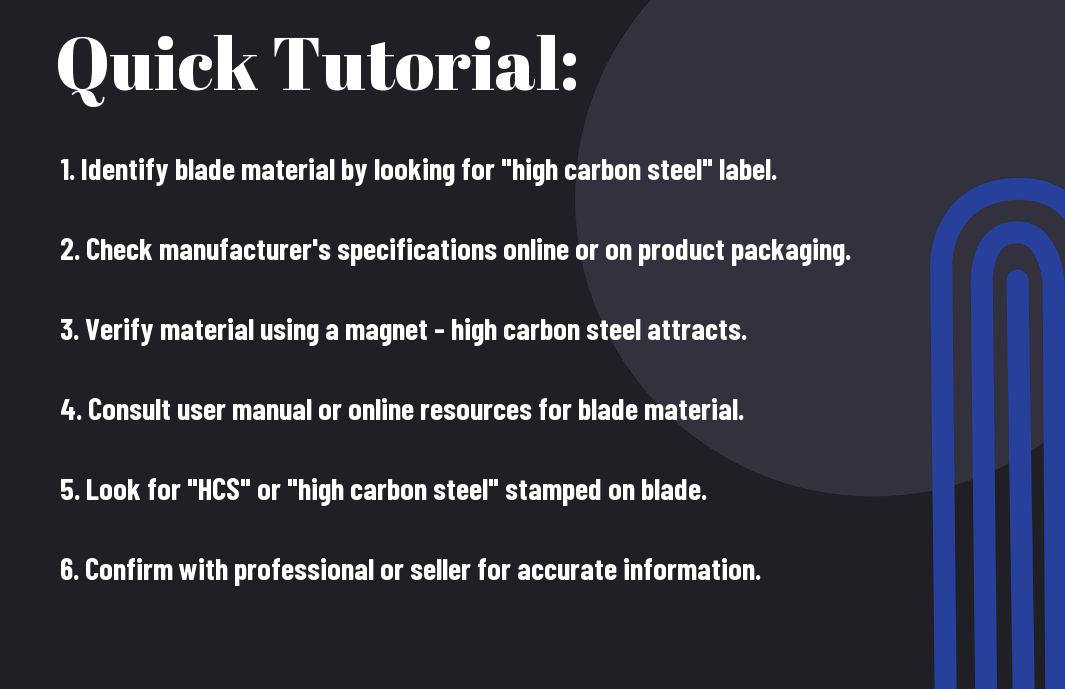

Identification of High Carbon Steel Blades

Despite the similar appearance of various circular saw blades, not all are made from high carbon steel. Identifying high carbon steel blades is crucial for ensuring their durability and performance in cutting applications.

Markings and Specifications

You can identify high carbon steel blades by checking for specific markings and specifications provided by the manufacturer. Look for labels indicating the material composition, such as “high carbon steel” or “HC Steel,” along with details on the blade’s hardness and durability.

Testing for Steel Composition

While visual inspections can provide some clues, testing for steel composition is the most reliable method to determine if a circular saw blade is made from high carbon steel. Conducting chemical tests or using specialized equipment can help verify the blade’s material makeup accurately.

Markings such as “HC Steel” or “High Carbon Steel” are critical indicators of a blade’s quality and performance. Higher carbon content in steel blades leads to increased hardness and wear resistance, making them ideal for cutting tough materials efficiently and with precision.

Maintenance and Longevity

Caring for High Carbon Steel Blades

High carbon steel circular saw blades are known for their durability and sharp cutting edges. To ensure they maintain their cutting efficiency and longevity, it is important to care for them properly. After each use, clean the blade thoroughly to remove any build-up of sap, resin, or other debris that can dull the blade. Store the blade in a dry place to prevent rust and corrosion. Regularly inspect the teeth for any damage and sharpen them as needed to keep the blade performing at its best.

Impact of Steel Quality on Blade Life

There’s a direct correlation between the quality of steel used in circular saw blades and their overall lifespan. Blades made from high carbon steel are more durable and resistant to wear and tear compared to those made from lower-quality steel. Investing in a high-quality blade may initially cost more but will save you money in the long run as they last longer and require less frequent replacements.

Caring for your high carbon steel circular saw blade by following proper maintenance practices and investing in a quality blade will not only prolong its lifespan but also ensure optimal cutting performance for your woodworking projects.

Choosing the Right Blade

After purchasing a circular saw, one of the most critical decisions is selecting the right blade for your needs. The blade you choose can significantly impact the quality of your cuts and the efficiency of your work.

Factors to Consider

Factors to consider when choosing a circular saw blade include blade material, number of teeth, blade diameter, and arbor size. The material of the blade determines its durability and what materials it can effectively cut. The number of teeth impacts the speed and smoothness of the cut, with more teeth providing a finer finish. Blade diameter and arbor size must match your saw to ensure compatibility. Recognizing these factors will help you make an informed decision.

Recommendations for Various Applications

On different applications, such as woodworking, metal cutting, or masonry work, it’s crucial to choose the right blade. The best blade for woodworking is one with a high tooth count for fine cuts, while metal cutting blades should have fewer teeth and be made of a harder material. Masonry blades need abrasive materials like diamond to cut through tough materials effectively. The choice of blade can make a significant difference in the quality and efficiency of your work.

Summing up

As a reminder, circular saw blades are not typically made of high carbon steel. Instead, they are commonly made of tool steel, which can vary depending on the manufacturer and the specific requirements of the saw blade. If you are looking for more detailed information about the plate steel type used in circular saw blades, you can refer to circular saw blade plate steel type? for further insights.

FAQ

Q: Are circular saw blades made of high carbon steel?

A: Yes, most circular saw blades are made of high carbon steel. This type of steel is known for its durability and ability to hold a sharp edge for a long time, making it ideal for cutting through various materials.

Q: What are the advantages of using high carbon steel for circular saw blades?

A: High carbon steel is valued for its strength, hardness, and wear resistance, which are vital qualities for cutting tools like circular saw blades. It allows the blades to maintain sharpness and withstand high-speed cutting operations without dulling quickly.

Q: How can I tell if a circular saw blade is made of high carbon steel?

A: High carbon steel blades are often labeled or specified as such by the manufacturer. You can also look for characteristics such as hardness, strength, and the ability to hold a sharp edge as indicators of high carbon steel. Additionally, high carbon steel blades may have a higher price point compared to blades made from other materials.