Are Circular Saw Blades hardened? Understanding Blade Durability and Performance

Connoisseurs of woodworking may ponder the crucial question – Are circular saw blades hardened? Understanding this necessary aspect of saw blade manufacturing can make a significant difference in your woodworking experience. The hardness of a circular saw blade plays a vital role in its longevity, durability, and cutting performance. In this comprehensive tutorial, we will probe into the intricacies of circular saw blade hardness, exploring its impact on cutting efficiency, blade wear, and safety measures. Knowing whether your circular saw blades are hardened can empower you to make informed decisions when selecting the right blade for your woodworking projects.

Key Takeaways:

- Circular saw blades are typically hardened: Most circular saw blades are made from high-speed steel or carbide, which are both hardened materials. This hardening process helps to increase the durability and longevity of the blade.

- Hardened circular saw blades are more resistant to wear: Hardened blades can withstand the high heat and friction generated during cutting, reducing wear and tear on the blade. This also helps maintain sharpness for longer periods of time.

- Proper maintenance is necessary for maintaining blade hardness: While circular saw blades are hardened, they can still become dull over time with regular use. It’s important to follow proper maintenance procedures, such as cleaning and sharpening the blade, to ensure it performs effectively.

The Manufacturing of Circular Saw Blades

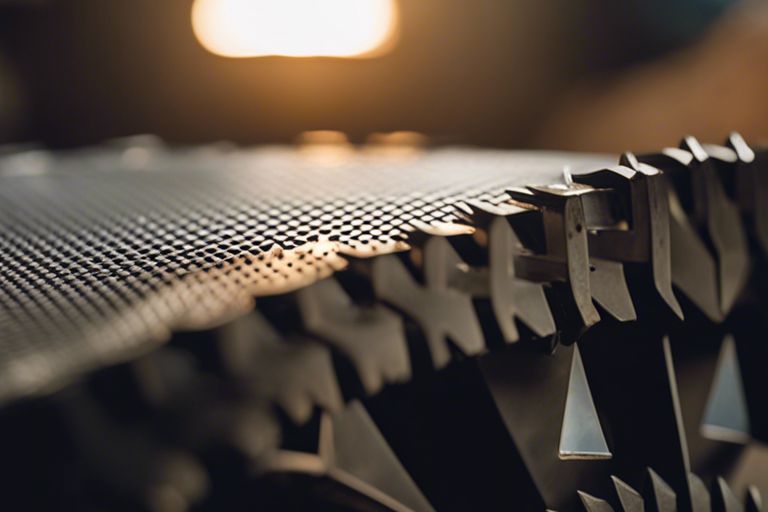

Materials Used in Blade Construction

With advancements in technology, circular saw blades are typically made from high-quality steel, such as carbide-tipped blades which offer exceptional durability and cutting precision. These materials are carefully selected to ensure the blade can withstand the rigors of cutting through various materials with ease.

How are the circular saw blades hardened

An important step in the manufacturing process of circular saw blades is the hardening process. This process involves heating the blade to high temperatures and then rapidly cooling it to increase its hardness and durability. This hardening process is crucial as it ensures the blade maintains its sharpness and cutting ability for a longer period, even when used on tough materials.

Used in conjunction with tempering, where the blade is heated again to reduce its brittleness, the hardening process results in a blade that strikes the perfect balance between hardness and toughness. This ensures that the blade can maintain its cutting edge even under stressful conditions, making it a reliable tool for various cutting applications.

Characteristics of Hardened Circular Saw Blades

Durability and Longevity

There’s no doubt that hardened circular saw blades are known for their exceptional durability and longevity. These blades undergo a heat treatment process that significantly increases their hardness and resistance to wear. This means they can withstand tougher working conditions, such as cutting through hard materials like metal or dense hardwood, without losing their sharpness.

Performance in Cutting Applications

The performance of hardened circular saw blades in cutting applications is unmatched. The hardened teeth on these blades stay sharp for a longer period, ensuring clean and precise cuts every time. The heat treatment process also improves the overall cutting speed and efficiency, making these blades ideal for professional use in various industries.

The enhanced cutting performance of hardened circular saw blades is due to their ability to maintain sharpness over an extended period, reducing the need for frequent sharpening and blade replacements.

Maintaining Hardened Circular Saw Blades

Cleaning and Storage

For proper maintenance of hardened circular saw blades, it is crucial to clean them regularly after each use. Remove any debris, resin, or sap on the blade with a soft brush or cloth. Store the blade in a dry place to prevent corrosion and damage.

Sharpening and Care

To ensure the longevity of your hardened circular saw blades, regular sharpening is crucial. While maintaining the blade’s original angle is important, it is also vital to check for any cracks or damage. Use proper tools and techniques to sharpen the blade without compromising its hardness.

Maintaining proper sharpening techniques is crucial to avoid any accidents or injuries while using the circular saw. Always follow the manufacturer’s guidelines for sharpening angles and use safety equipment such as gloves and goggles.

Alternatives to Hardened Blades

Coated Blades

Even though hardened blades are a popular choice, coated blades can offer a viable alternative. These blades have a special material coating that enhances their durability and resistance to wear and tear. The coating can also reduce friction, resulting in smoother cuts and extended blade life.

Non-Hardened Blades

Little known to many, non-hardened blades can be a suitable option for certain applications. These blades are not hardened to the same extent as typical circular saw blades. While they may not be as durable or long-lasting as hardened blades, non-hardened blades can still provide satisfactory performance for lighter cutting tasks.

Hardened blades are known for their superior hardness, strength, and durability. They are less likely to dull quickly and can withstand heavy-duty cutting tasks without losing their sharpness.

To wrap up

From above discussion, it is clear that circular saw blades are indeed hardened, mainly to increase their durability and cutting efficiency. This hardness poses a challenge for those looking to repurpose saw blades for projects such as knife making. However, with the right techniques and tools, it is still possible to repurpose circular saw blades for various DIY projects. For more information on knife making out of circular saw blades, you can visit here.

FAQ

Q: Are circular saw blades hardened?

A: Yes, most circular saw blades are hardened to improve their durability and cutting performance. Hardening of the blades involves heat treatment processes that make the metal stronger and more resistant to wear and tear.

Q: How do hardened circular saw blades differ from non-hardened ones?

A: Hardened circular saw blades have a higher level of hardness and toughness compared to non-hardened blades. This means they are less likely to dull quickly and can maintain sharpness for a longer period of time, resulting in cleaner cuts.

Q: Can hardened circular saw blades be sharpened?

A: Yes, hardened circular saw blades can be sharpened, but it may require special tools and techniques due to their hardened surface. It is recommended to seek professional sharpening services to ensure the proper sharpening of hardened blades without compromising their structural integrity.

Common Questions answered

What are circular saw blades made of?

What circular saw blade do I use for laminate flooring?

What circular saw blade for MDF?

What circular saw blade for trimming doors?

What saw blade do I need for this job?